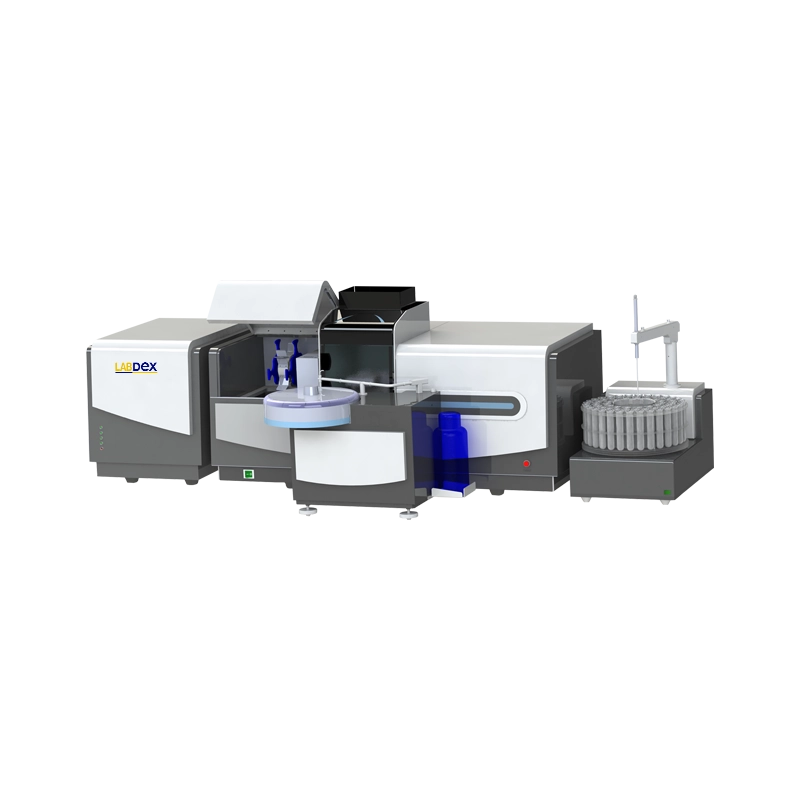

Atomic Absorption Spectrophotometer LX703AAS

Description

Atomic Absorption Spectrophotometer LX703AAS is an integrated flame/graphite furnace atomization system where the graphite system is fully automatic. They analyze the concentration of elements in a liquid sample based on energy absorbed from certain wavelength of light. They are equipped with turrets that can hold multiple lamps to reduce downtime between samples or allow for sequential analysis.

Specifications

| Wavelength range | 190-900nm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wavelength accuracy | ≤±0.25 nm | ||||||||||||

| Wavelength repeatability | ≤±0.15nm | ||||||||||||

| Spectral bandwidth | ≤±0.02 nm | ||||||||||||

| Stability of baseline |

|

||||||||||||

| Light source | Eight lamp position design Automatically rotating light stand that can be automatic switch and optimize Two lamp positions to support high-performance hollow cathode lamps Each lamp position can be lighted and preheated optionally | ||||||||||||

| Optical system |

|

||||||||||||

| Flame system | 10cm Ti burner head for air-acetylene flame, emission burner provided Burner head height and horizontal position automatic adjustment, with burner angle rotatable Direct forming spray chamber with corrosion-resistant material PPS Automatic ignition with high precision mass flow control system realizing fully automated fuel gas flow control an adjustment | ||||||||||||

| Graphite furnace system | Longitudinal heating GF system with temperature up to 3000℃, heating rate more than 2500℃/s Two temperature control modes selectable: optical and constant voltage. Both slope and stepped temperature programming are available Fully automatic GF height and horizontal position setting and optimization Inner gas, external gas and make up gas are controlled separately. Circulating water and gas flows monitoring system is equipped | ||||||||||||

| Detection and Data processing system |

|

||||||||||||

| Background correction | D2 lamp background correction, with correction ability more than 30 times S-H background correction, with correction ability more than 30 times | ||||||||||||

| Voltage | Main unit single phase: AC, 110V/220V Main unit power consumption: 0.2kVA Graphite furnace single phase: AC, 220V Graphite furnace power consumption: 5.5kVA | ||||||||||||

| Packing dimension (L x W x H) and Gross weight | Main unit: 1280 x 750 x 830 mm, 150 kgs Graphite furnace power supply: 660 x 600 x 800 mm, 70 kgs Graphite furnace auto-sampler: 540 x 440 x 420 mm, 22 kgs Flame auto-sampler: 540 x 440 x 520 mm, 20 kgs |

Features

- Provided with automatic 8-lamp turret, automatic adjustment of lamp current and optimization of light beam position

- To perform flame emission analysis, flame emission burner head can be installed for alkali metals

- Parameters like Wavelength scanning, peak picking, change in spectral bandwidth, optimization of position parameters, automatic ignition and gas flow setting are done automatically

- Data processing system: provided with analytical methods – Working curve auto-fitting standard addition method, automatic sensitivity correction, automatic calculation of concentration and content with windows operating system software

- Experiments can be repeated 1~99 times along with automatic calculation of mean value, standard deviation and relative standard deviation

- Equipped with multi task functions- sequential determination of multi-elements in the same sample, condition reading- with model function and result printing- measured data and final analytical report printout in excel

- Provided with standard RS-232 serial port connection

- AAS analysis is made under windows operating system which is easy-to-use with fast parameter setting and optimization

- In order to increase the sensitivity in flame analysis, two high performance HCLs can be mounted on the lamp turret

- The optical system consisting of outer light path, C-T type grating monochromatic, and back light path, which is in the upper right of the instrument, is controlled by the computer

- Real-time monitoring of flame status, air pressure, etc. Automatically shutting off the gas circuit and alarm in abnormal status

- Equipped with alarm and automatic protection to fuel gas leakage, abnormal flow, insufficient air pressure and abnormal flame extinction in flame system

- Protection function and alarms for insufficient carrier gas and protective gas pressure, insufficient cooling rate supply and over-heating in graphite furnace system

- Real-time monitoring for GF conditions and heating program etc., with automatic power cut-off and alarm when abnormal detected, such as water and gas control error, graphite tube installation mistake, and temperature control problem etc.

Applications

- Used for testing the metal element concentration analyze in agriculture, chemical, environmental study, food, mining, and petrochemical, pharmaceutical industry.